Best Steel is a specialist in stainless steel, carbon steel, galvanized steel, nickel-based alloy, and PPGI/PPGL coils & sheets. We also provide a professional cutting service.

WE'RE ON MAP

- Shibei District, Qingdao City, China

EMAIL ADDRESS

social media

Up of the best quality

PPGI PPGL Coil

HIGH QUALITY PRODUCTS

PPGI PPGL Coil

PPGI and PPGL coils are steel sheets coated with zinc or aluminum-zinc alloy (Galvalume) and then painted with a high-quality paint layer. This process involves cleaning, applying a chemical treatment, and then painting the steel sheet to provide a durable, colorful finish. The paint layer offers additional protection against corrosion and enhances the aesthetic appeal of the steel. These coils come in various colors, patterns, and finishes to meet specific application requirements.

We have a wide range of prepainted galvanized products, covering hot dip prepainted galvanized steel and Electro prepainted galvanized steel. We support customization of pre-coating process, including PVDF, PE, SMP and HDP. Pattern styles include RAL color, brick, flower and wood grain, we can customize according to your requirements.

PRODUCT SPECIFICATION:

| Prepainted Coil / Sheet(PPGI) | |

| Standard | ISO,JIS,AS EN,ASTM |

| Grade | Q195 Q235 Q345 |

| SGCC SGCH SGC340 SGC400 SGC440 SGC490 SGC570 | |

| SGHC SGH340 SGH400 SGH440 SGH490 SGH540 | |

| DX51D DX52D DX53D DX54D DX55D DX56D DX57D | |

| S220GD S250GD S280GD S320GD S350GD S400GD S500GD S550GD | |

| SS230 SS250 SS275 | |

| Width | 20-2800mm |

| Thickness | 0.2-150mm |

| Substrate | Cold rolled Substrate / Hot rolled Substrate |

| Color | Ral Color Systerm or as per buyer’s color sample |

| Surface treatment | Chromated and oiled, and ant-ifinger |

Typical Chemistry:

The chemistry of PPGI and PPGL coils involves the composition of the base steel, the zinc or aluminum-zinc alloy coating, and the paint layer:

Base Steel:

- Carbon (C): 0.05% to 0.25%

- Manganese (Mn): 0.20% to 1.50%

- Phosphorus (P): ≤ 0.04%

- Sulfur (S): ≤ 0.05%

- Silicon (Si): ≤ 0.50%

Zinc Coating (for PPGI):

- Zinc (Zn): Typically 99% zinc.

- Aluminum (Al): Often added in small amounts (0.1% to 0.3%) to improve the coating’s uniformity and adhesion.

Aluminum-Zinc Alloy Coating (for PPGL):

- Zinc (Zn): 43.4% to 55% by weight.

- Aluminum (Al): 55% to 43.4% by weight.

- Silicon (Si): 1.6% by weight.

Paint Layer:

- Polyester, Silicone Modified Polyester (SMP), Polyvinylidene Fluoride (PVDF), and Epoxy: Depending on the application requirements.

Physical Properties:

PPGI and PPGL coils exhibit several key physical properties that make them suitable for a wide range of applications:

- Tensile Strength: Typically ranges from 270 MPa to 550 MPa, depending on the grade and thickness.

- Yield Strength: Generally ranges from 240 MPa to 320 MPa.

- Elongation: Varies from 20% to 40%, indicating good ductility and formability.

- Coating Thickness:

- PPGI: Zinc coating thickness typically ranges from 20 to 275 g/m².

- PPGL: Aluminum-zinc coating thickness typically ranges from 30 to 150 g/m².

- Paint Thickness: Typically ranges from 20 to 25 microns on the top side and 7 to 15 microns on the bottom side.

Specifications:

PPGI and PPGL coils are produced according to various standards and specifications to ensure quality and compatibility:

- ASTM A653/A653M: Standard specification for steel sheet, zinc-coated (galvanized) or zinc-iron alloy-coated (galvannealed) by the hot-dip process.

- ASTM A792/A792M: Standard specification for steel sheet, 55% aluminum-zinc alloy-coated by the hot-dip process.

- EN 10169: Continuously organic coated (coil coated) steel flat products.

Features:

Key features of PPGI and PPGL coils include:

- Excellent Corrosion Resistance: The zinc or aluminum-zinc coating provides a robust barrier against rust and corrosion, significantly extending the product’s lifespan.

- Durability: Enhanced durability due to the strong coating and paint layers, making it suitable for various environmental conditions.

- Aesthetic Appeal: Available in a wide range of colors, patterns, and finishes, offering an attractive appearance for visible applications.

- Good Formability: High ductility and formability allow the material to be easily shaped and fabricated into different configurations.

- Cost-Effectiveness: Provides a cost-effective solution compared to other corrosion-resistant materials like stainless steel.

- Ease of Installation: Lightweight and easy to handle, making installation straightforward.

- Versatility: Available in various sizes, thicknesses, and finishes, making it adaptable to a wide range of applications.

- Low Maintenance: Requires minimal maintenance over its lifespan, reducing long-term costs.

FREE SAMPLES

Our dedication to customer satisfaction is evident in our Free Sample offering. We provide complimentary samples of our products, allowing customers to evaluate quality and suitability firsthand. By offering Free Samples, we prioritize transparency, trust, and informed decision-making.

QUICK QUOTES IN 12 HOURS

Customer service is paramount, reflected in our quick 12-hour quote turnaround time. We prioritize efficiency, providing accurate and competitive pricing information promptly. This commitment to responsiveness ensures informed decision-making and project continuity.

PLANT TOURS AND VIDEO INSPECTIONS

We offer flexibility and transparency through video inspections and on-site plant tours. Our specialization in carbon steel products underscores our expertise and long-term supply capabilities.

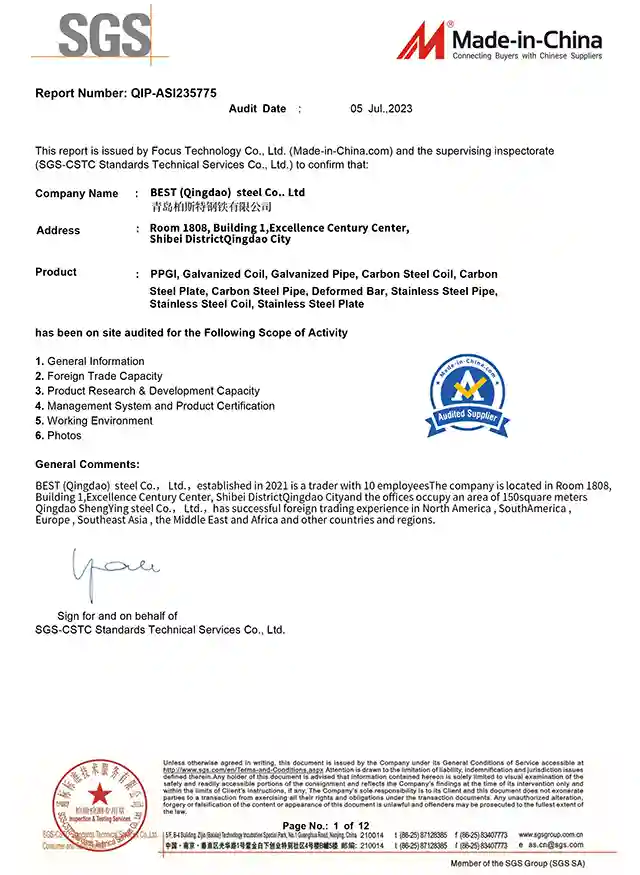

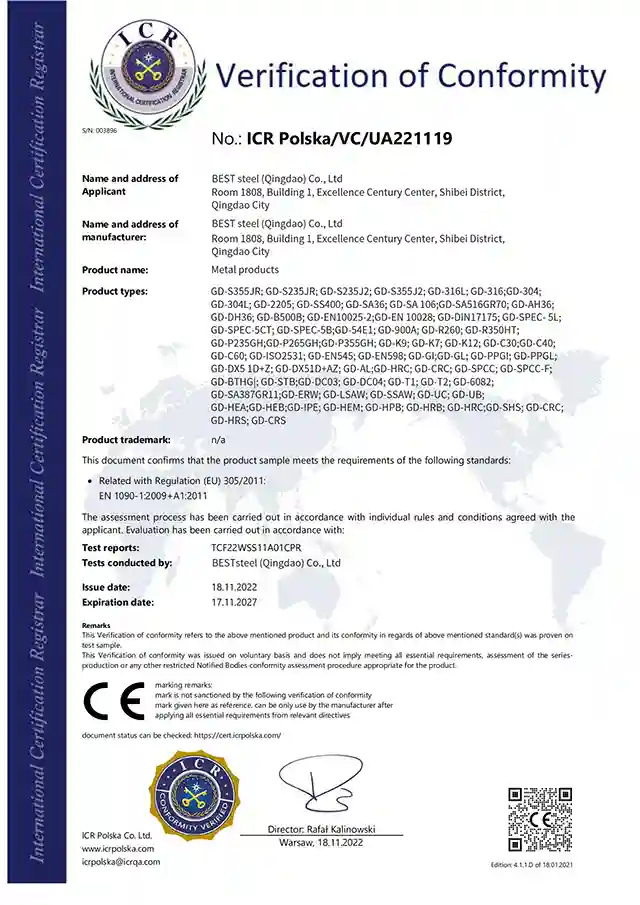

ISO, BV, TUV, SGS CERTIFICATION

Our strength lies in stringent quality control practices, exemplified by our ISO 9001 Certification. This internationally recognized standard signifies our commitment to consistently exceeding customer expectations. Thorough inspections, testing, and compliance checks guarantee superior quality.

FLEXIBLE MINIMUM ORDER QUANTITY (MOQ)

We pride ourselves on a flexible MOQ policy, enabling customers to benefit from a low MOQ of just 1 ton. We accommodate diverse needs, ensuring accessibility and convenience. Our flexible MOQ fosters strong partnerships with businesses of all sizes, reinforcing our commitment to customer satisfaction.

QUESTION ANSWERS

Frequently Asked Questions

At Best Steel, we take pride in our commitment to quality, customization, and reliability. Our FAQ section is designed to address common inquiries, but please feel free to contact us for any specific questions or requirements you may have. We look forward to serving your steel needs with dedication and expertise.

Best Steel is a leading steel manufacturing and distributioncompany that provides high-quality steel products to various industriesand applications.

Best Steel offers a comprehensive range of steel products, including sheets, coils, bars, rods, pipes, tubes, structural shapes, and specialty items.We provide materials in various grades and dimensions to meet the specific needs of our customers.

Yes, one of our key strengths is customization.We work closely with customers to tailor steel solutions to their exact specifications.Whether it’s adjusting dimensions, altering grades, or providing specialty coatings, we can accommodate various customization requests.

Our manufacturing facilities are strategically located in various regions, allowing us to serve customers worldwide efficiently.Our global presence ensures timely delivery and meets diverse customer demands.

Best Steel is committed to the highest quality standards.We adhere to international quality certifications such as BV,TUV,SGS to ensure that our steel products meet or exceed industry expectations for strength, durability, and reliability.

Environmental sustainability is a top priority for Best Steel. Our production processes emphasize energy efficiency, waste reduction, and responsible sourcing of materials. We continually seek eco-friendly practices to reduce our environmental footprint.

Yes, we have a team of experienced engineers and technical experts who provide guidance, consultation, and support.Whether you need assistance with material selection, project planning, or technical inquiries, our team is here to help.

You can contact our dedicated customer service team directly through our official website or our sales representatives.We are responsive and ready to assist with inquiries, orders, or support.

It is free, depend on the value of the sample. The cost of the freight would be charge.

Best Steel is committed to being a responsible corporate citizen.We engage in various community development initiatives, support local educational programs, and prioritize the well-being of our employees.Our aim is to make a positive impact on the communities in which we operate.